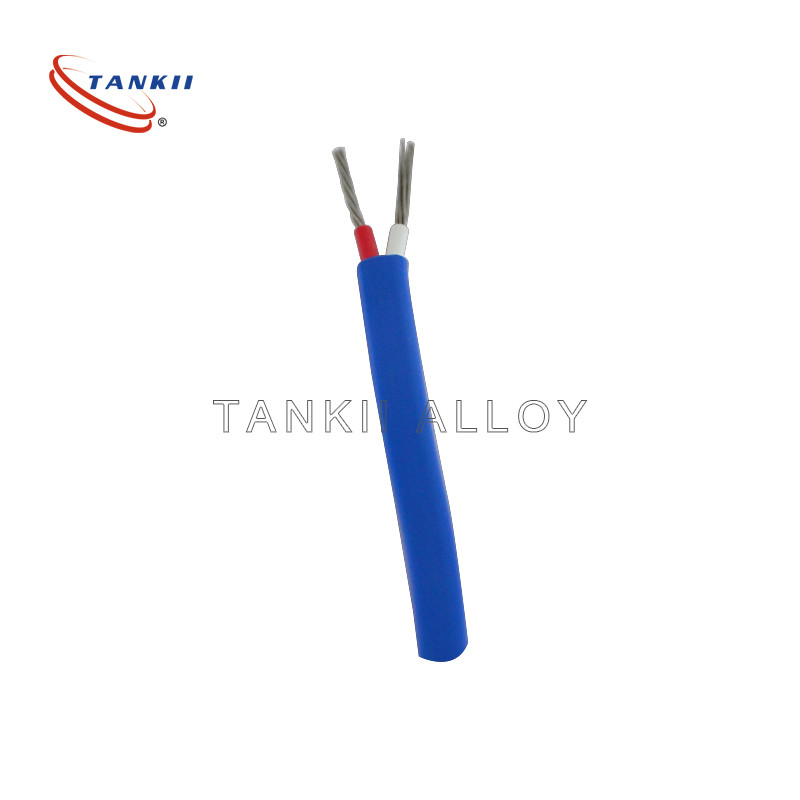

ISO Certified K Type Thermocouple Extension Wire Chromel Alumel

With Fiberglass Insulation

Product Description:

What is the difference between K type and other types of

thermocouple cables?

The K type thermocouple cable has several differences compared to

other types of thermocouple cables:

- Material composition:

- K type: The positive conductor of a K-type thermocouple cable is made of

a nickel-chromium alloy, and the negative conductor is made of a

nickel-aluminum alloy.

- J type: The positive electrode is pure iron, and the negative electrode

is a copper-nickel alloy (also known as constantan).

- T type: The positive electrode is pure copper, and the negative electrode

is a copper-nickel alloy.

- S type: The positive electrode is a platinum-rhodium alloy (e.g., 10%

rhodium and 90% platinum for the S type), and the negative

electrode is pure platinum.

- Temperature range:

- K type: It can be used in the temperature range of -200°C to 1300°C,

which is relatively wide and suitable for many industrial

temperature measurement scenarios

- J type: The applicable temperature range is from -200°C to 800°C, but it

is usually used below 500°C because the oxidation rate of the iron

hot electrode accelerates at higher temperatures.

- T type: The usable temperature is -200°C to 350°C, and it has the best

stability in the -200°C to 0°C temperature range.

- S type: The long-term use temperature is 1300°C, and the short-term use

temperature can reach 1600°C. It is suitable for high-temperature

environments with high accuracy requirements.

- Sensitivity and accuracy:

- K type: It has relatively high sensitivity and good linearity in a

certain temperature range, but its accuracy is not as high as that

of some precious metal thermocouples.

- E type: It has high sensitivity and is suitable for measuring small

temperature changes, but its thermoelectric potential uniformity is

relatively poor.

- T type: It has high accuracy in the low-temperature range, but its

sensitivity and accuracy decline at high temperatures.

- S type: It has the highest accuracy level among all thermocouples and is

often used as a standard thermocouple in high-precision temperature

measurement.

- Cost:

- K type: As a cheap metal thermocouple, it is cost-effective and widely

used in various industrial fields.

- S type, R type, B type and other precious metal thermocouples: These have high accuracy, good stability, and high-temperature

resistance, but their prices are relatively expensive.

- Resistance to environmental factors:

- K type: It has strong oxidation resistance and can be used in oxidizing

and inert atmospheres. However, it cannot be used directly in

high-temperature environments with sulfur, reducing or alternating

reducing-oxidizing atmospheres, or in a vacuum.

- J type: It can be used in vacuum, oxidation, reduction, and inert

atmospheres, but the positive iron electrode oxidizes relatively

quickly at high temperatures, so its use is limited in some

high-temperature environments.

- T type: It has poor oxidation resistance at high temperatures, so the

upper limit of its use temperature is restricted.

Technical Parameters:

| Technical Parameter | Value |

|---|

| Product Name | Thermocouple Extension Wire |

| Cable Type | K Type TC Cable |

| Connector Type | Miniature, Micro, Etc. |

| Insulation | PVC, Silicone, Etc. |

| Cable Length | 100m, 200m, 300m |

| Voltage Rating | 220V |

| Cable Color | Black, White, Etc. |

| Connector Material | K, J, T, E, N, Etc. |

| Temperature Range | -200℃ To +1000℃ |

Applications:

Thermocouple cable has a wide range of applications, including:

- Industrial manufacturing:

- Metallurgy: In steelmaking, ironmaking, and other metallurgical processes,

thermocouple cables are used to monitor the high temperatures in

furnaces, such as blast furnaces, electric furnaces, and

converters. This helps to control the smelting process and ensure

the quality of the metal products.

- Chemical industry: Chemical reactions often occur under specific temperature

conditions. Thermocouple cables are used to measure the temperature

in reactors, distillation columns, and other equipment to ensure

the normal progress of chemical reactions and the safety of the

production process.

- Ceramics and glass manufacturing: The production of ceramics and glass requires high-temperature

firing and melting processes. Thermocouple cables are used to

monitor the temperature in kilns and furnaces to control the firing

temperature and ensure the quality of the products.

- Power generation: In power plants, thermocouple cables are used to measure the

temperature of boilers, steam turbines, and other equipment to

monitor the operating status of the equipment and ensure the safe

and efficient operation of the power generation system.

- Automotive industry: Thermocouple cables are used in the automotive industry to

measure the temperature of engine exhaust gases, catalytic

converters, and other components. This helps to monitor the

performance of the engine and the emission control system, and is

also used in the testing and development of new automotive engines.

- Aerospace industry: In the aerospace field, thermocouple cables are used to measure

the temperature of aircraft engines, rocket engines, and other

high-temperature components. This is crucial for ensuring the

safety and reliability of aerospace vehicles during flight.

- Food industry: In the food processing industry, thermocouple cables are used to

measure the temperature of ovens, sterilization equipment, and

other processing equipment to ensure the safety and quality of food

processing.

- Laboratory and scientific research: Thermocouple cables are widely used in laboratories and

scientific research institutions for temperature measurement in

various experiments and research projects. For example, in material

research, chemical experiments, and biological research,

thermocouple cables are used to measure the temperature of samples

and reaction systems.

- HVAC systems: In heating, ventilation, and air conditioning systems,

thermocouple cables are used to measure the temperature of air,

water, and other media to control the operation of the system and

ensure the comfort of the indoor environment.

Customization:

Our thermocouple cables are manufactured in China, ensuring

excellent quality and durability. With a temperature range of -200℃

to +1000℃, our thermocouple wire is perfect for a variety of

industrial and commercial settings.

In addition to the standard cable diameters of 0.5mm, 1.0mm, 2.0mm,

and 2.5mm, our thermocouple cables are also available in various

insulation materials such as PVC, silicone, and more. We can

manufacture cables with 2, 3, 4, or more cores, depending on your

specific requirements.

To ensure easy installation and use, our thermocouple cables come

with connector shells of different sizes, including 6.35mm, 4.2mm,

and more. With our product customization services, you can choose

the most suitable connector shell size for your application.

Trust Tankii for all your thermocouple cable needs, including

thermocouple type K and other types. Contact us today to discuss

your specific requirements and request a quote.

FAQ:

Q: What is the brand name of this Thermocouple Cable?

A: The brand name of this Thermocouple Cable is Tankii.

Q: What are the different model numbers available for this

Thermocouple Cable?

A: The different model numbers available for this Thermocouple

Cable are KX/KC, JX, EX, TX, NX, SC

Q: Where is this Thermocouple Cable manufactured?

A: This Thermocouple Cable is manufactured in China.

Q: What are the temperature ranges supported by this Thermocouple

Cable?

A: The temperature ranges supported by this Thermocouple Cable vary

depending on the model number. Please refer to the product

specifications for more information.

Q: Is this Thermocouple Cable suitable for use in harsh industrial

environments?

A: Yes, this Thermocouple Cable is designed to be durable and

reliable in harsh industrial environments.